The entire foodservice industry is experiencing widespread labor shortages. Every business—including school cafeterias, sports venues, and restaurants—is experiencing a lack of personnel, which is resulting in organizations being forced to offer limited service or to close entirely. However, it continues to be evident that food monitoring programs help in dealing with these labor shortages.

Labor Shortages in the Foodservice Industry

From fast food to fine dining and from hospitals to universities, foodservice industry staff numbers have yet to recover to pre-pandemic levels. This lack of front- and back-of-house staff in the food industry has resulted in significantly less visibility and accountability than ever before, which is having a direct effect on vital aspects of daily operations.

Temperature Monitoring Problems

Insufficient amounts of available staff is manifesting in problems like temperature monitoring and correction in refrigerator and freezer units. With no one to notice these temperature fluctuations or equipment malfunctions, repairs are either delayed or simply do not occur. This can leave a business with no other choice but to throw hundreds or even thousands of dollars of food away.

Unfinished Checklists

Staff shortages can also result in maintenance and kitchen task checklists being left unfinished, and the completion of manual tasks left undone until individuals are able to come into work. This only places restaurant businesses further behind schedule and at a great disadvantage where it comes to gauging overall business performance and food quality.

Compromised Food Safety

The continued lack of personnel also negatively affects food safety; an organization that is unable to maintain its food safety requirements and brand standards will not be able to meet its requirement to protect public health, risking business shutdown and damage to their brand’s reputation.

The Benefits of Food Monitoring With Technology

There are many ways that technology is improving workflow efficiencies, food safety, and food quality.

Temperature Sensors

Temperature sensors detect changes occurring outside normal ranges in refrigerators and freezers. The temperature sensor alerts workers to possible mechanical issues with these units, allowing restaurant owners to preserve food by transferring it to a backup refrigeration unit.

IoT sensors allow for the continuous collection and processing of temperature data from hot and cold temperature appliances. Without IoT sensors, data would need to be collected and processed manually either by new staff or added to the duties of existing staff, possibly resulting in the work overload or higher wages.

Where the collection and processing of data may take hours for a staff member to complete manually, IoT sensors are able to collect and process incredible volumes of data in a fraction of that time. Additionally, when temperatures go out of the specified range automatic alerts are sent to notify management and allow quick response and correction.

Workflow Automation

Workflow automation is another type of technology that is helping food service businesses through enduring labor shortages. The ability to automate tasks previously completed by humans offers a host of benefits.

The completion of tasks can be documented and assured completion with automation, which results in far fewer human errors, regardless of the way in which it is used in a foodservice business. This allows foodservice companies to maintain a far higher standard of quality.

Digital Workflow Checklists

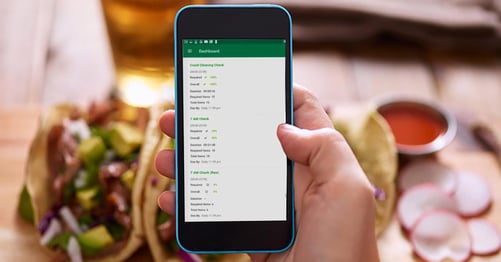

Customizable digital checklists allow managers to track, document, and ensure safety across their organizations. Whether it’s a list of inventory, a safety checklist, or creating staff schedules, digital checklists can be used for literally all aspects of a business.

Your Complete Food Monitoring Solution

The ComplianceMate food safety and back-of-house system and information engine is an innovative and reliable way to maintain HACCP compliance. The operational checklists help you manage your budget and meet quality benchmarks.

Checklists also assist in documenting shift notes, allowing you to compensate for short staffing when necessary, as well as monitor current and past staff progress.

The LoRaWAN temperature sensors wirelessly transmit information about temperature and humidity through the heavy insulation, concrete, and stainless steel found in commercial kitchens. Your entire food storage benefits from around-the-clock monitoring, which alerts you to temperature changes via email or text.

ComplianceMate’s real-time reporting offers food service managers the ability to view real-time and historical rates of completion and compliance from any web-enabled device. Owners can use ComplianceMate’s data analytics to streamline their entire operation and improve outcomes at every level.

Insufficient food monitoring and continued labor shortages don’t have to mean dealing with extended negative impacts to your business; ComplianceMate allows you to harness the power of technology for the benefit of your entire organization.

Learn more about the many powerful benefits of ComplianceMate today; visit our website for the details or call us to be put in touch with a knowledgeable representative: 678-346-0380.